PLCs: Workings, Applications, Limitations

- Kartik Buddha

- May 18, 2023

- 4 min read

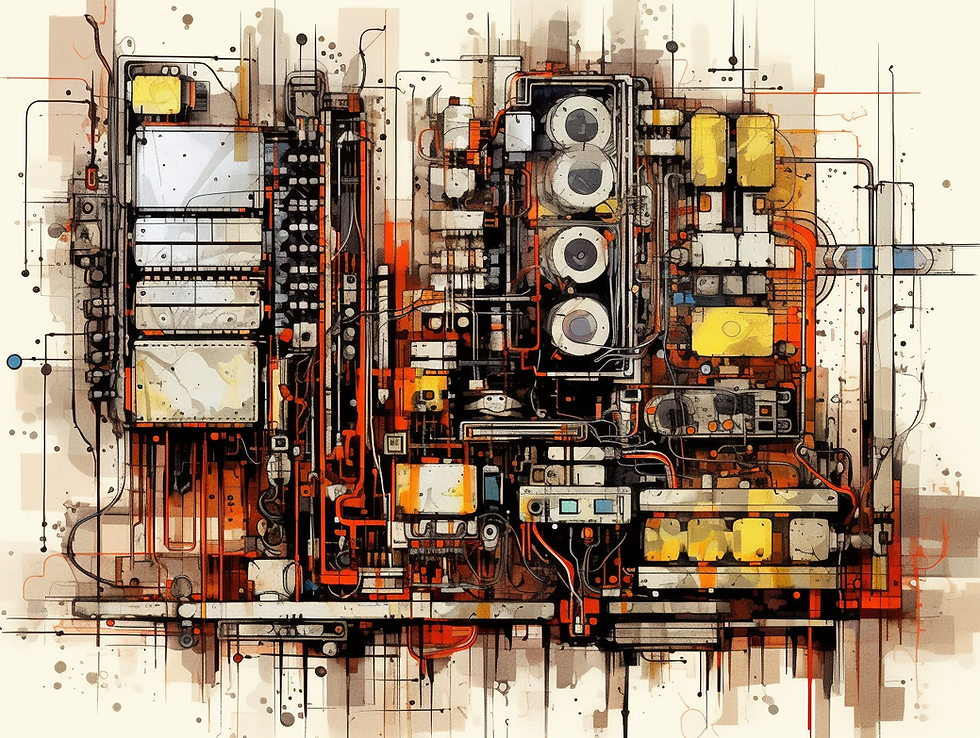

In the realm of industrial automation, Programmable Logic Controllers (PLCs) play a pivotal role in controlling and monitoring complex systems. In this article, we will explore the inner workings of PLCs, diving into their technical aspects while shedding light on their practical applications. Additionally, we will discuss scenarios where PLCs prove highly effective and cases where alternative control systems may be more suitable.

Understanding PLCs: How They Work

Central Processing Unit (CPU)

At the heart of a PLC lies the Central Processing Unit (CPU). This powerful microprocessor processes program instructions, reads input signals from various sources, executes control logic, and generates output signals. The CPU is responsible for ensuring efficient and timely operation of the entire PLC system.

Input/Output (I/O) Modules

PLCs interface with the physical world through Input/Output (I/O) modules. These modules serve as the bridge between the digital or analog signals from sensors, switches, and other devices, and the CPU. Input modules receive signals from the external world, converting them into a digital format that the CPU can interpret. Output modules, on the other hand, receive digital commands from the CPU and convert them into appropriate signals to control actuators, relays, or other devices.

Memory

PLCs utilize different types of memory to store and manage critical information. The program memory contains the user-defined control logic, often created using ladder logic or other programming languages. Data memory stores variables, timers, counters, and other operational data required during program execution. Additionally, PLCs employ non-volatile memory to store the program and system configuration, ensuring data persistence even during power outages.

Scan Cycle

PLCs operate in a continuous loop called the scan cycle. During each cycle, the PLC performs a series of steps, including reading input values, executing the user-defined program logic, updating output values, and managing system tasks. The scan cycle ensures real-time control and responsiveness in industrial applications.

Applications of PLCs

Industrial Automation

PLCs find wide-ranging applications in industrial automation, enabling precise control over manufacturing processes, assembly lines, robotic systems, and material handling. They excel in tasks such as motor control, sequential operations, monitoring and regulating environmental parameters, and managing safety systems.

Process Control

PLCs play a vital role in process control applications, such as those found in chemical plants, power generation facilities, and wastewater treatment plants. They provide precise control over variables like temperature, pressure, flow rate, and level, ensuring optimal operation and maintaining desired process parameters.

Safety Systems

PLCs are extensively used in safety-critical applications, where reliable and fail-safe control is paramount. They enable the implementation of safety interlocks, emergency shutdown systems, and other protective measures to ensure the well-being of personnel and equipment.

Limitations and Disadvantages of Using PLCs

While PLCs offer numerous advantages in industrial control systems, it's important to be aware of their limitations and potential disadvantages. Understanding these aspects can help engineers make informed decisions when selecting control solutions. Let's explore some of the limitations of PLCs:

Scalability and Flexibility

PLCs excel in applications where a fixed set of control requirements is known in advance. However, they may face challenges when it comes to scaling up or accommodating dynamic changes. Adding new functionality or modifying the control logic in a PLC often requires significant reprogramming or hardware modifications, leading to potential downtime and increased costs.

Complex Programming

Programming PLCs typically involves specialized languages like ladder logic, which may require additional training and expertise for software engineers. The graphical nature of ladder logic can become complex and challenging to maintain, especially in large-scale control systems. Developing and debugging PLC programs can be time-consuming and may involve a steep learning curve.

Limited Computational Power

Compared to general-purpose microcontrollers or computer systems, PLCs generally have limited computational power. This limitation can impact the execution speed of complex control algorithms or data processing tasks. In applications where extensive data analysis or advanced computational capabilities are required, alternative control systems with higher computational power may be more suitable.

Higher Costs

PLCs can be more expensive compared to alternative control solutions, especially for small-scale or simple control applications. The initial cost of acquiring the PLC hardware and software, along with the associated programming and maintenance expenses, can be significant. For budget-constrained projects or applications with basic control requirements, PLCs may not be the most cost-effective choice.

Integration with IT Infrastructure

Integrating PLCs with existing Information Technology (IT) infrastructure, such as data logging, remote monitoring, or cloud connectivity, can be challenging. PLCs typically operate in isolated control networks and may require additional hardware or software components to establish seamless communication and data exchange with IT systems.

Limited Debugging and Diagnostic Capabilities

Identifying and troubleshooting issues within a PLC system can be challenging due to limited debugging and diagnostic capabilities. Unlike software-based systems that offer extensive debugging tools and error logging, PLCs often rely on diagnostic LEDs, basic error codes, or manual observation for fault detection and troubleshooting.

Dependency on Vendor-Specific Platforms

PLCs are often tied to specific vendors or manufacturers, which can result in a level of vendor lock-in. This dependency may limit the availability of compatible hardware, software, and technical support options. Migration or integration with different PLC platforms can be complex and time-consuming, impacting system scalability and future upgrades.

Real-time Requirements

PLCs excel in real-time control, providing deterministic execution and precise timing. However, for applications demanding ultra-fast response times or extremely tight timing constraints, specialized real-time control systems or dedicated microcontroller-based solutions may be more suitable.

PLCs form the backbone of industrial automation, offering robust control capabilities and real-time operation. By understanding the technical intricacies of PLCs and their applications, engineers can harness their power to automate complex processes, ensure safety, and optimize industrial systems. While PLCs are invaluable in a wide array of scenarios, it's essential to consider factors like complexity, cost, and real-time requirements when choosing the most appropriate control system.

Comments